Submerged Arc Welding (SAW)

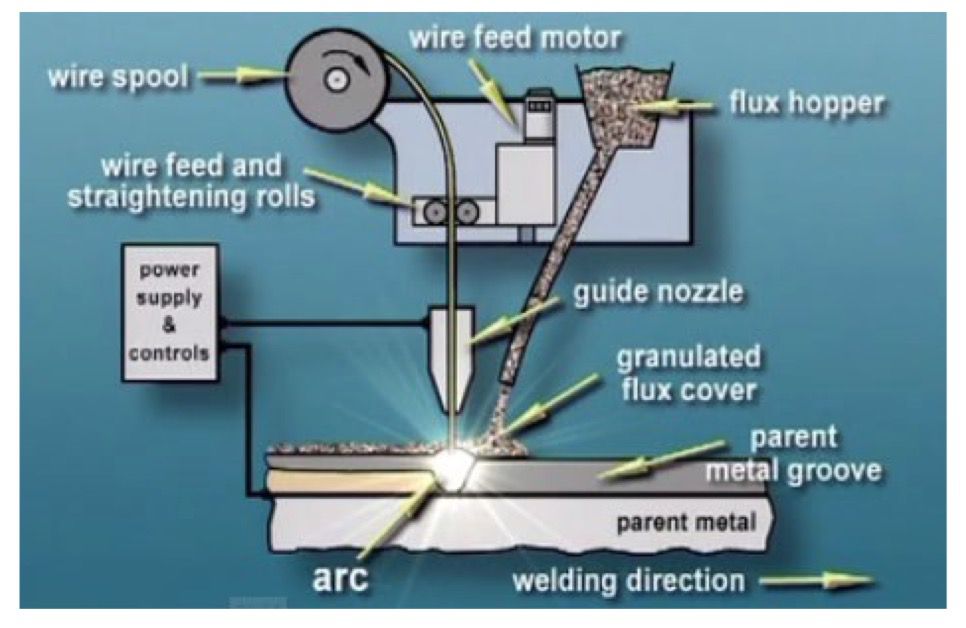

Submerged arc welding uses a continuously fed bare wire consumable electrode, 1.6 to 6.4 mm diameter, to produce a weld pool which is protected from atmospheric contamination by a separately supplied shielding flux in fused or agglomerated form.

It is possible to feed more than one consumable wire electrode into the weld pool at the same time to increase production rates by up to a factor of eight times compared to using a single wire.

Submerged arc welding is normally fully mechanised, but may be used manually or in a fully automatic mode.

The arc and molten weld metal are completely submerged beneath the layer of shielding flux and are not visible to the eye, however, protection against the arc light is advisable.

The flux also provides additives to the weld, removes impurities from the weld and provides a thermal blanket (slag) protecting the weld as it cools down. The remaining unfused flux is recovered for re-use after the removal of impurities and sieving.

It may be specified that the flux used can only contain a limited amount of recycled flux, e.g. a maximum of 25%. If this is the case the recycled flux must always be thoroughly mixed in with the new flux before use.

An advantage of the submerged arc welding process is that very high welding currents can be used to produce the rapid deposition of heav weld beads without spatter. Although it is possible to use 5,000 amps or more to produce for example a 37 mm thick weld in one pass, it is more usual to restrict the current to around 1000-2000 amps and deposit a multi-run weld because of the improvement in metallurgical properties.

Power source and equipment

Both AC and DC power sources are used with SAW, with a typical current output of 400-1500 amps. Both drooping characteristic and flat characteristic power sources are used. Because of the high current draw off, a 100% duty cycle capability is recommended.

Arc-blow is a deviation of the arc due to 20 magnetic influences caused during welding and is most likely to occur when using DC polarity although the preparation can have a large effect on the 30 severity, resulting in excessive spatter/ lack of fusion defects/ slag entrapment.

Flat characteristic DC power sources are the type most commonly used for applications where the current does not exceed 1000 amps, they are also the best for the high speed welding of thinner steel sections.

Above 1000 amps and for thicker sections, drooping characteristic AC is preferred and works best if the sine waves are square because polarity reversal is instantaneous. AC is also preferable for multi-wire techniques and applications where arc-blow is a problem.

Single, twin or triple wire feed systems are commonly used, all feeding into the same weld pool. All the wires may be live, or dead fillers may be applied. In a multi-wire application, the leading wire is usually DC +ve polarity, this will limit the risk of burn through, although deep penetration will be achieved because of the high current used. AC would normally be used for the remaining wire(s), or dead fillers could be used, or a combination of both.

Application areas

Submerged arc welding is widely used in ship building, structural steel work, general engineering applications, and for the fabrication of pipes and pipelines, e.g. double jointing stations. Carbon steel, alloy steel and stainless steels are the main materials welded using this process.

Because of the heavy deposition rates and fluid slag, it is only possible to weld in the flat or horizontal vertical position. However, circumferential welds may be made on pipes or vessels. For this application the welding head remains stationary while the work piece rotates beneath it.

Wires to BS EN ISO 14171, Fluxes to BS EN ISO 14174

Weld quality and properties are influenced by the choice of wire and flux. The determination of the best wire and flux combination to use to give optimum qualities is often a case of trial and error. The BS EN ISO 14171 – Wire electrodes and flux combinations for submerged arc welding of non-alloy and fine grain steels, gives requirements for the wire and flux, designates a coding system for SAW wires and fluxes, and also offers guidance on choice.

Fluxes

Fluxes for SAW are divided into two types:

- Fused - granulated,

- Agglomerated - powdered.

Fluxes can be further classified depending on their basicity or acidity.

Fused fluxes

Fused fluxes are manufactured as follows: the ingredients are mixed and melted at a high temperature, the mixture is then poured onto large chill blocks or directed into a stream of water to produce granules which have a hard glassy appearance. The material is then crushed, sieved for size, and packaged.

Advantages of fused fluxes include:

- good chemical mix achieved,

- they do not attract moisture (not hydroscopic) this improves handling, storage, use, and weldability. Any moisture present is easily removed by low temperature drying,

- the easy removal of impurities and fine particles etc. when recycling.

The main disadvantage is the difficulty in adding deoxidants and ferro- alloys. These would be lost during the high temperature manufacture. The maintenance of a controlled flux depth is considered critical.

Agglomerated fluxes

All the flux materials are dry mixed and then bonded with either potassium or sodium silicate, they are then baked at a temperature below the fusion or melting point and therefore remain as a powder which is sieved for size and packaged.

Advantages of agglomerated fluxes include:

- easy addition of deoxidants and ferro-alloys,

Disadvantages include:

- tendency for flux to absorb moisture and a difficult redrying procedure,

- possibility of molten slag causing porosity,

- difficult re-cycling, i.e. the removal of impurities and sieving.

Flux basicity or classification

A certain amount of oxygen will exist during welding, some will remain in the weld metal either in gaseous form or as oxide inclusions. The oxygen can be controlled by chemical reactions with the molten flux.

Basic oxides tend to be more stable than acidic oxides. Generally the higher the basicity of a flux, the less the production/formation of oxygen (porosity) and oxide inclusions, leading to an improvement of weld metal strength.

Fluxes for SAW may be classified as follows: